language

Company:Guangdong PENGLAI Intelligent Equipment Co.,LTD

Factory Address:403B, No.99 Qiaocheng East RD,Nanshan District,Shenzhen,Guangdong ,China

Factory ADDRESS:St George Industrial Park,XinYu Road,ShaJing Town,Bao'an District,Guangzhou City,China

Contact:Jack Du

Cel:+86-15811882441

Phone:+86-755-86718316

Fax:+86-755—25417648

Email:penglaipacking@gmail.com

Email:postmaster@penglaipacking.com

Skype:turnanewleaf

Website:www.penglaichina.com

www.youtube.com/user/penglaichina

YX Series filling machine G -10,20,100,500 Small Quantitative Filling Machine Manual

First, an overview of

YX series G-10, 20,100,500 small-scale quantitative filling machine is the use of electric, crank, piston-type structural design of automatic quantitative liquid dispensing machines, suitable for hospital preparation room, ampoule, eye drops, a variety of oral liquid, Shampoo and various quantitative filling agent; but also can be used for a variety of chemical analysis of quantitative test in a row plus a variety of liquid fluid, especially for large, medium and small-scale sub-loaded liquid pesticide plant.

Second, Feature of this instrument

1,A simple structure, reliable, fault less;

2, using cone pistons, sealing performance, separate injection fluid volume accuracy, easy to adjust the amount of fluid;

3, touch on both the liquid is made of stainless steel, and to facilitate loading and unloading, separate injection can be sterile;

4 cylinder, putting the piston made of stainless steel material, corrosion resistance, wear;

5, the speed continuously adjustable, easy to operate.

Third, Specifications

|

Model |

Voltage (v) |

Power(w) |

Sub-liquid volume(ml) |

Subpackage Speed |

Accurancy of filling |

Weight (kg) |

Volume (mm) |

|

YX-G10 |

220 |

20 |

0.2-10 |

Adjustable (Up to 40 times / min ) |

±0.5% |

6 |

200×145×350 |

|

YX-G20 |

220 |

30 |

5-20 |

Adjustable (Up to 30 times / min ) |

±0.5% |

7 |

220×145×355 |

|

YX-G100 |

220 |

60 |

10-100 |

Adjustable (Up to 30 times / min ) |

±1% |

13 |

300×180×480 |

|

YX-G500 |

220 |

120 |

50-500 |

Adjustable (Up to20 times / min 分) |

±1% |

18 |

310×235×580 |

Fourth , Use Methods

1, the machine must be ground before the work of well-grounded, then the amount of equipment based on different sub-select the appropriate standard syringe. The general sub-range of 0.2-1ml loading used 1ml syringe; 1-5ml

used 5ml syringe; 5-10ml used 10ml syringe; 20ml models, using 20ml glass Enemator; 100ml aircraft, the use of 100ml glass enema device, ( can also use the factory produced a special stainless steel filling system); 500ml models, using a special stainless steel production factory filling system.

2, (FZH) DLG -10,20,100 ml model according to (Figure 1) shows, the syringe inner core ① ② set aside to cover screw on the syringe on the inner core (Note: 10ml syringe diameter models due to large differences in , need to select the size of their cylindrical gasket), and with the set screw and lower its base ② ③ suitable fastening (removable injection

Device must pay attention to cleaning).

3, such as (Figure 2) will be on the seat clamp on the syringe jacket cover ① ②

The outlet side will properly tighten the nut on both sides (with 5ml injection

Will be put on when you tighten the hub, pay attention to screw in too tight, outer

Casing fragile). Note: 10ml models with the adjustment cover, 20 type,

100, 500 did not.

4, will be packed syringe inner core, jackets assembled into one,

At this point liquid injection system assembly is completed.

5, such as (Figure 3) to the valve ① upward arrow, the arrow mark

Outwards with the nut fixed on the screw ②.

6, the assembly of a complete liquid injection system, according to (Figure 4)

shows, The injection fluid system components, the next hole, respectively, align the upper and lower solid

Fixed rod, set in the bearing on the physiognomy and to its external face and the bearing

Ping. Bottom assembly, not to screw cover and crank ① collide,

Rotate the crank case on the issue of an abnormal sound when you (correctly according to installation

Between the sleeve and the crank when the screw a distance of about 1mm), an injection fluid system correctly

After installation, fastening the upper and lower set screws. Hose will be injected with a short

Devices and valves connecting Tsui ② phase. Into the fluid inlet pipe access

③, pick out the fluid outlet pipe ④. In order to prevent access to liquid tube wrapped

Around, the control card into the chassis and out of liquid collateral ear mouth.

7, hand crank toggle ①, should be able to freely rotate, or assembly

Errors, should check the liquid injection system is firmly anchored in the rotating bearings of the

On the basis having any error (Figure 4) can be properly installed.

8,100 ml with factory produced models, such as a special stainless steel filling

System, installation method please refer to 500ml models.

Fifth , fluid volume adjustment

1, like (Figure 5) shows. First, spin nut ① and then transferred

Section screw ② so that the next change with the location of the fixed pole. To syringe

Of the push-pull length has also been changed, to the amount of sub-free adjustment of the head mounted

The. ② adjustment screw clockwise increments, and vice versa reduction, which

Pointer with the instructions. With 5ml syringes, 5ml to see the side marked with

10ml syringes marked with 10ml to see the side of 20,100,500 type direct

See ruler, pointer quantitative, but because of the thickness of each needle is different from real

Volume of inter-packing error, in order to needle scale prevail, but also at the beginning of sub -

When installed the most accurate look at the amount of dosage cups.

2, adjust the nut ① tightened immediately after, so that the following fixed-pole

With the crank set firmly tight.

3, such as (Figure 6) shows. Loosen the nuts ①, according to different injection

Sliding injector to determine the length of the correct position of the fixed rod ②. Lower solid

Rod set a good tone after the crank to top dead center so that after the syringe, then

Put up the syringe jacket tube is about 2mm, so that the top bad needle, and then

① the nut tightened only after the boot.

4, the machine assembled correctly and opened the switch, the machine work,

Driven by a crank-driven syringe pump fluid up and down, adjust the speed knob,

Select the appropriate sub-loading speed of the work to regulate the speed governor

Knob clockwise sub-loading speed and slow the contrary.

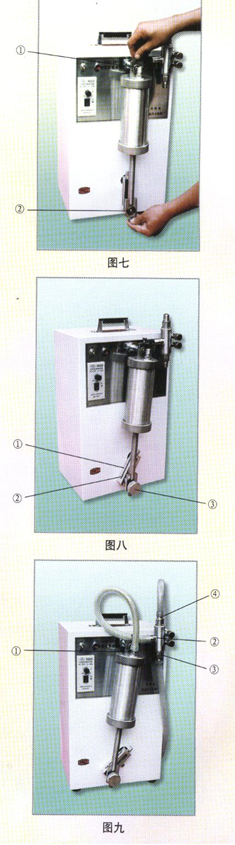

Sixth , 500ml models using the method of installation

1, such as (Figure 7) shows. 500ml stainless steel sink will be dedicated

Install the system from top to bottom alignment hole on the solid bar, respectively ①, under the solid rod ②, sets

On the bearing on the physiognomy and to its external face and bearing flat, tighten two

Set screws.

2, such as (Figure 8) shows. See ruler ①, ② pointer quantitative,

Then screw down the fixed pole and tighten the fastening nut ③.

3, such as (Figure 9) shows. Short rubber hose out of the filling system

Water and valves connecting Tsui Tsui ① ② phase, into the fluid inlet pipe access ③,

Water and valves connecting Tsui Tsui ① ② phase, into the fluid inlet pipe access ③,

The stainless steel countersunk head then the other end into the drain pipe to be installed into the liquid. Out

Liquid pipe pick outlet ④, in order to prevent fluid control winding, the outlet pipe

Card into the chassis of collateral ear mouth.

4, open the master switch the power to regulate the speed controller knob, so that

Achieve their needs filling speed. Note: The filling speed large-capacity

Degree should be slower, small-capacity could be appropriately adjusted quickly.

Seventh ,fault and maintenance

1, can not boot normally after the crank rotation, fault:

A: If (Figure 10) shows. On the fixed-pole side, the syringe

Push the liquid inside and outside the tube when the top rate, leading to the crank does not spin, should Loosen the screw

Cap ①, ② will be moving up on the fixed-pole suitable position, it will nut

① tightened.

B: syringe assembly between the inner and outer cylinders caused by dirty Card

In prison, must remove the syringe cleaning.

C: Note the end of load bearing parts of hydraulic systems. So that it can not be normal

Work, according to (Figure 4) as shown in heavy equipment.

2, injection liquid uneven joints tighten the end, there is leakage phenomenon, the need

Can be further tightened.

3, the machine rotated normal, but no points of liquid discharge, fault:

A: There are foreign bodies valve needs cleaning;

B: valve within the upper and lower two thimble placed on the error, (2

Thimble are cutting-edge down, can not install anti-).

C: 100,500 ml-based liquid such as the Pistons brought out under the mouth with liquid leakage

Leakage, it should open the cylinder ring to replace random. Note: The ring with the

φ65 × 3.1 Acid-alkali-ring.

Eigth, sterilization methods and rinse

1, according to (Figure 4) shows, Loosen the upper and lower set screws, remove the liquid injection system as a whole disinfection, decontamination or demolition respectively.

2, will be placed into the drain pipe cleaning fluid in the boot clean.

3,500 ml filling models in practice there may be errors in the official pre-filling quasi-date with the cylinder volume.

4, filling machine bearing Model: 10 type, 1000087,20 type, 100 type, 1000088,500 type ,6001-ZZ.

5, filling machine needle, 10-type standard 5ml or 10ml syringe, 20ml glass enema with 20-type devices, 100 with the 100ml glass enema device.

Copyright © Guangdong PENGLAI Intelligent Equipment Co.,LTD