language

Company:Guangdong PENGLAI Intelligent Equipment Co.,LTD

Factory Address:403B, No.99 Qiaocheng East RD,Nanshan District,Shenzhen,Guangdong ,China

Factory ADDRESS:St George Industrial Park,XinYu Road,ShaJing Town,Bao'an District,Guangzhou City,China

Contact:Jack Du

Cel:+86-15811882441

Phone:+86-755-86718316

Fax:+86-755—25417648

Email:penglaipacking@gmail.com

Email:postmaster@penglaipacking.com

Skype:turnanewleaf

Website:www.penglaichina.com

www.youtube.com/user/penglaichina

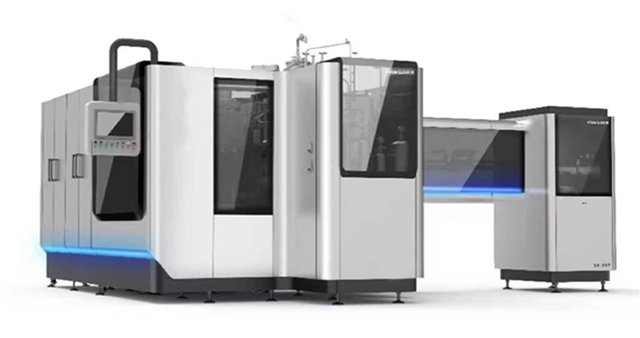

Product Showcase: AFP Series Aseptic Blow-Fill-Seal System for Plastic Container

1. General

The aseptic plastic packaging blow-fill-seal system can realize the processes of bottle blowing, filling, sealing, and slitting through the following functions. The equipment

mainly includes the following components: extruding system, mold-shifting clamping component, filling component, trimming component, hydraulic system, CIP &SIP

system, Mold, cooling system, pneumatic control system, vacuum system, electrical control system.

Parameters of BFS machine:

2. Process Flow:

The extruder directly drives the screw through a motor to convert the loose plastic particles into molten plastic. The thermoplastic extruder with an aspect ratio of 25: 1 is

equipped with a cast aluminum heater and a temperature control module with a water-cooling device on the screw. The extruder provides precise control of the

three-stage extrusion temperature; a variable-speed, fully-enclosed air-cooled motor drives the extruder through a hardened and ground-processed reducer.

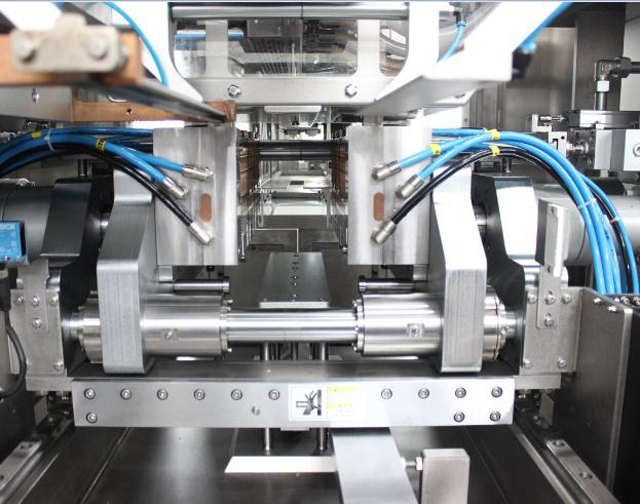

4. Mold Moving and Locking Part

The whole part consists of the locking mechanism, the transfer mechanism and the feeding mechanism. Main die and sealing die provide support. Move mold movement driven by 180 degree spiral rotary cylinder mold swing arm, swinging arm reciprocating

motion driven clamping mechanism. The feeding mechanism is driven by two hydraulic cylinders. Picking mechanism are all designed with proximity switch to monitor

whether the oil cylinder movement in place, can effectively detect the discharge oil cylinder each working position, colleagues’ timely feedback to the entire operating system, can make troubleshooting response quickly and efficiently.

5. Filling Part

The filling parts of sterile plastic packaging and blowing filling system are filled by time-pressure method. Configuration has a terminal filter (0.22 microns) and liquid buffer tank liquid buffer tank equipped with pressure sensor through the sterile

compressed air or nitrogen fill high frequency voltage and high frequency pressure to ensure that the pressure inside the tank balance, through high precision weighing module in weighing control filling liquid surface height. Each filling needle of the

device is equipped with a separate diaphragm valve control. The filling time of each filling valve can be set independently by the HMI control interface to make

fine adjustment to the filling amount.

6. Scrap incision parts and conveyor lines

The trimming part cuts the sheet into products and waste: the sensor detects the sheet to control the trimming mold work, and the trimming mold is powered by a hydraulic system.

7. CIP&SIP System

All product contact parts are made of 316L stainless steel. The equipment contains fully automatic control of product filtration and sterile airline CIP/SIP and other aseptic

systems. The equipment is equipped with four sterile filters. All filter shells are equipped with built-in integrity test ports. The filter integrity test system integrated on the machine detects the air and product filters installed on the machine. The test

is set by the auxiliary panel on the machine. Comply fully with GMP specification.

8. Mold

The mold includes three parts: bottle phantom, sealing mold and holder. Each section has individually adjusted cooling water and vacuum lines. The mold is made of

high-quality bronze alloy. After the heat treatment process, it has no deformation,high hardness, high strength, rust prevention, good polishing performance and long service life.

9.Hydraulic System

Hydraulic system mainly consists of hydraulic oil tank, duplex hydraulic pump, accumulator, heat exchanger and hydraulic valve, which provides power for all cylinders. The cylinder model oil cylinder adopts proportional control, which can set

the operating speed of each movement at different stages in the operation interface of the main engine, which can effectively guarantee the product quality.

Samples of bottles to be made by BFS equipment:

Configuration of model YX-AFP3 BFS machine:

After-sales service on PENGLAI-brand Machines

Guarantee: for all the machines, it claims one year for guarantee. (Excluded from the

warranty are problems due to accidents, misuse, misapplication, storage damage,

negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE

GUARANTEE)

Installation: after the machine arrives at your factory, if you need it, our technician will go to your place to install and test the machine and also training your worker to

operate the machine (The time of train depend on your worker).

The expenses (air ticket, food, hotel, the traveling fee in your country) should be on your account and you need to pay for the technician USD230 per day. also, you can go to our factory to do training.

After-sale service: If you get a problem with the machine, our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account. (above-mentioned).

Copyright © Guangdong PENGLAI Intelligent Equipment Co.,LTD