language

Company:Guangdong PENGLAI Intelligent Equipment Co.,LTD

Factory Address:403B, No.99 Qiaocheng East RD,Nanshan District,Shenzhen,Guangdong ,China

Factory ADDRESS:St George Industrial Park,XinYu Road,ShaJing Town,Bao'an District,Guangzhou City,China

Contact:Jack Du

Cel:+86-15811882441

Phone:+86-755-86718316

Fax:+86-755—25417648

Email:penglaipacking@gmail.com

Email:postmaster@penglaipacking.com

Skype:turnanewleaf

Website:www.penglaichina.com

www.youtube.com/user/penglaichina

Our West African customer from Senegal&Congo bought one machine model YX-M520-L series three lanes packaging machinery ; With about 30working days we finished manufacturing the machinery and tested it for more than 3hours with the function like

how to wind the film&to install the materials hopper ; The machine should be connected with the high power transfer pump as we advised to our customer because it can save a lot workforce ;

The machine has been shipped with the Maersk boat for the fast shipping; but it is well know to African countries the shipping time takes longer time than the counterparts in EU&American regions;

Our customer should wait for another 30days to get the machines;

As below there is the basic information for the international business transaction:

Samples sent from customers:

Bank slip for deposit&balance collection:

Testing video for machinery three lanes packaging:

Wooden case packaging for machinery packing via ocean:

YX-LM520-L03 multilanes packing machine VFFS packaging bagging solution is a full automatic packing machine with high quality and high performance made by this co.,ltd through introducing, digesting and absorbing advanced technology from abroad, and has a series of automatic functions, such as automatic-delivering, measuring, bag-making, sealing, date printing, finished product exporting.

This machine adopts high precision servo film-transferring system, PLC program control, advanced touch-type human machine interface, photoelectric automatic positioning tracing and digital type temperature control, which make operation of the complete machine simpler, perfect, and it is the first-choice equipment for improving producing efficiency, decreasing labor intensity, upgrading packing level in food packing industry.

Performance and Specifications of multilanes packing machine VFFS bagging system:

|

power supply |

single-phase 220V/50Hz |

|

total power |

3.5KW |

|

packing material |

OPP/CPP、CPP/PE MST/PE、PET/PE |

power of horizontal sealing heating sheet (4-sheet in series) |

800W/220VAC |

|

|

thickness of packing film |

0.05-0.08mm |

power of vertical sealing heating sheet (2-sheet in series) |

500W/220VAC |

|

|

maximum width of packing film |

1000mm |

measuring range |

1-40mL(2-20g) |

|

|

|

220mm (width)x300mm (length) |

air pressure used |

6.5MPa |

|

|

packing speed |

5-60 packages/minute |

air consumption |

600L/min |

|

|

weight of complete machine |

700kg |

|

overall dimension |

1850(length) X123(width) X 2320(height) |

|

suitable materials to be packed |

Liquid and powder and granules etc. |

|||

Notice: Packing speed according to packing material and packing weight .packing materials should be used in rolls, the outer diameter should be ≤400mm, inner diameter of framework should be Φ75mm, thickness of compound packing material should be 0.05-0.08mm, surface of the packing material should be smooth without wave, in the range of 10mm on the side should not have printed pattern and characters (namely the grounding should be pure), contrast between color dot and grounding should be obvious.

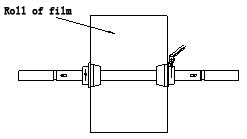

2.A►Arrangement plan of the complete machine

3. Installation notice

1). Packing machine and finished product transferring machine should be connected with 220VAC power supply with earth leakage protection and a current of more than 10A

2). Automatic lifting machine should be connected with 3-phase 380VAC power supply with earth leakage protection and open-phase protection and a current of more than 10A.

3). Please don’t forget to install earth wire.

4). Connect the air source with entrance of triplet of packing machine.

5). Use elevator to transfer material into big material hopper at the top of packing machine.

6). Install date printing ink ribbon

7). Install packing film.

1)Loosen the handle

2)Put in packing film

3) Bold line direction indicated in the chart passes through the packing film and move it along a continuous line, and lead the packing film into the bag former(Vertical sealing device should be opened first).

4)After lead the packing film enter bag former, adjust swing lever to make packing film pass through feeding tube. At this time, film-delivering switch and film motor at the bottom of packing machine enter automatic work status.

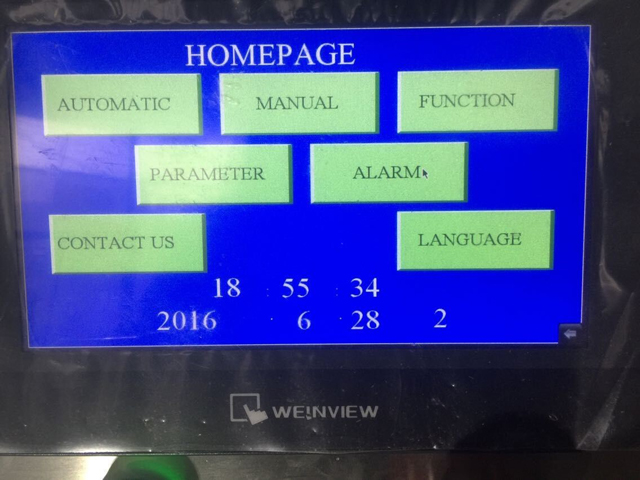

Touch screen language English-French Bilingual version

turn on ,display will show main menu,press English ,enter into second step :

1)Use hand touch parameter setting,Screen display as show

2)Touch next page,screen display as shown

3)If it is required to set parameters of various functions, touch the

function, it will display at the left end of the screen(as shown in the chart).

At this time, parameter can be amended, after the amendment, press the

key of return to confirm.

For example: amend horizontal sealing electric parameter: (change the original 0.65 into 0.75)

Touch the parameter of 0.65 of horizontal sealing, and it will twinkle, at the same time the screen displays digital table of the above chart, touch 0.75 of the digital table, then press the key of return.

4).Return homepage,touch the key of “Manual”,screen display

◆Touch pull filming ,pull filming once.

◆Touch make one bag stands,make one bag once

◆Touch horizontal sealing open, horizontal sealing jaw open.

◆Touch vertical sealing open,vertical sealing jaw open.

◆Touch cutter return: cutter action open.

5)turn to homepage, touch “auto”, screen displays

◆On: touch the key of “on”, packing machine will start.

◆Off: touch the key of “off”, packing machine will stop.

◆touch Alarm, display show

◆On:touch the key of “on”, open the alarm

◆Off:touch the key of “off”, turn off the alarm

Note: Establishment of parameters of packing machine is directly related with actual packing speed reached by packing machine. The bigger the value of various parameters, the lower the packing machine can reach, on the contrary, the quicker.

►Common faults, reasons and elimination

fault type

Operation methods

1) Open the total power of the machine, then preheat the vertical and horizontal sealing jaw date printer to the temperature setting and the horizontal sealing jaw which parts should be add some adequate lubricating oil.

2)Please pay attention to check the cleanliness of the tooth surface of vertical and horizontal sealing jaw.

3)Please check the equipment of the code date, packing film right or wrong, and check the Electronic location.

4)Open the switch of the printer of the date, and send the packaging film to the intended location. Open the motor, make 4-5 empty bags and then stop it. Check the bags is qualified, if done then open the materials falling switch to work.

5)First to shut down the materials falling switch when it needs to cut off the power,and then related the electrical power supply ,so as not to damage folders, tool damage.

Equipment maintenance

1)Before on or off duty, it is necessary to clean interior and exterior of the machine, thoroughly sterilize the parts passed by food

2)Before on or off duty every day, please check if 1/3 of the oil table of air source air source triplet oil storage jar is maintained, is less, it is necessary to pour 20# pure and clean oil until about 1/2 of the jar body.

3)Before start every day, pour 20# machine oil into oil cup on the horizontal sealing support until it becomes full.

4)Before off duty, it is necessary to take off unused packing film so as to prevent from bending supporting tube.

5)During the process of start, if material is clamped in vertical sealing or horizontal sealing, it is necessary to stop the machine immediately and clean tooth surface of vertical sealing or horizontal sealing with brass wire brush.

|

Name |

Remark |

|

cutter |

We advise you to change it once every three months |

►Spare parts list

horizontal sealing heater 4 set

vertical sealing heater 1set

interior hexagonal spanner 4-10mm 1 set

copper brush 120mm 1 piece

cutter 220mm 1set

oil kettle 150ml 1 piece

character grain 1 box

ALL RIGHTS RESERVED by ®PENGLAI INDUSTRIAL CORPORATION LIMITED

Copyright © Guangdong PENGLAI Intelligent Equipment Co.,LTD