language

Company:SHENZHEN PENGLAI Industrial Corporation Limited

Factory Address:403B, No.99 Qiaocheng East RD,Nanshan District,Shenzhen,Guangdong ,China

Factory ADDRESS:St George Industrial Park,XinYu Road,ShaJing Town,Bao'an District,Guangzhou City,China

Contact:Jack Du

Cel:+86-15811882441

Phone:+86-755-86718316

Fax:+86-755—25417648

Email:penglaipacking@gmail.com

Email:postmaster@penglaipacking.com

Skype:turnanewleaf

Website:www.penglaichina.com

www.youtube.com/user/penglaichina

to vertial round bottles labeling machines.Thus the whole line listed one by one as below:

Samples of labels and aerosol spray containers taken from USA customer

Ⅰ.Bottles bottle unscrambler with 1.0 diameter model YX-BS12

The Unscrambler is the driving force with frequency control table, put the bottle of artificial circular turntable, turntable rotation, will be transferred to the bottle conveyor belt has continued into the filling line for filling. Easy to use, you easily done with the bottle Unscrambler work.

Features of bottle unscrambler

1) Suitable for unscrambling disordered polyester bottles

2) Aligns bottles and discharges them by vacuum conveyor

3) PLC program controlled

4) Automatic.

5) High speed operation

Technical parameters of bottle unscrambler

* Diameter: Φ1000mm

* Speed: 430-50bottles/min(with Speed Controller, Schneider Inverter)

* Power: AC 220V±5% 50Hz 120W

* Material: SUS304

* Motor: Wanxin(Taiwan Brand, reducer without maintain)

* Variable Speed Controller: Taida

* Machine Weight: 80Kg

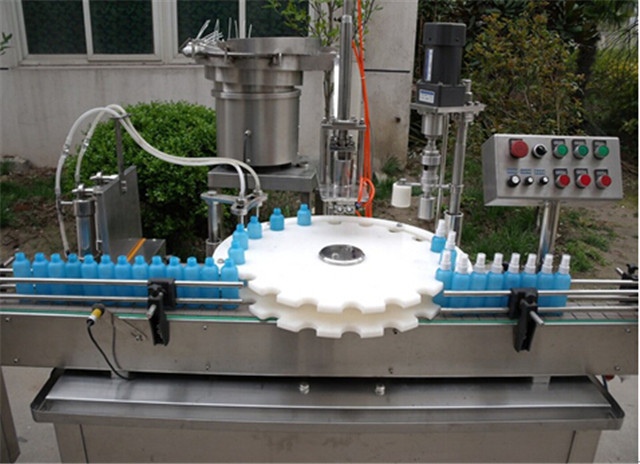

Ⅱ. Aerosol filling capping machine automatic model YX-20G

Application&description:

The filling line is developed based on the advanced technology overseas,especially applied for the aerosol filling.

The containers can be all-type round or irregular type as well as capping caps. Stainless steel piston pump finishs the filling,

capping by means of pneumatic driven and fall caps . The machine filling line is widely applied to daily chemical like pharmaceutical or cosmetics industry .

Features:

1、all the electronic parts are made from famous brands . the machine is characteristics of easy operation ,accurate filling, no bottles without filling,no capping without bottles

2、There is the position apparatus for capping in order that the spray feeding tubes can enter into the bottles without getting affected by either longer or bent tubes .

3、 Totally GM standard

basic parameter of filling machine spray aerosols :

Model YX-20G

filling volume: 5-500ml

Capacity:30-50BPM 60-90 BPM

filling accuracy:≤±1%

Supply power:380V/50Hz

capping rate:≥99%

air source:1.5M3/H 0.4-0.7Mpa

power:1.5 kw

N.w:500 kg

dimension:2000*1000*1500mm

Main configuration:

peristaltic pump: Langer, sino-germany joint

PLC: MITSUBISHI

Touch screen:WeinView

Materials: Stainless steel,contact part is made of SS316

Switch power:Taiwan,Mingway

Relay: Omron

Sensor:AUTONICS Korea

Frame:PENGLAI

Ⅲ.Automatic Vertical Non Sticker Labeling

Labeling machine for E-liquid bottles :

Automatic Non-sticker Vertical Sticker Labeling Machine is intended mainly for sticking label outside the side face of round or square bottles.The machine words stably and reliably, which leads to smooth labels, clearly printed dates and batch numbers(the printer allows three rows of characters).This machine is provided with a multiple control system, which assures automatic stop at the lacking or breaking of labels as well as at the lacking of bottles. This product conforms to the specifications of GMP absolutely. Which is widely used in pharmaceutical, foods and chemical industries

Characteristic of vertical non sticker labeling machine:

Labeling exact and high precision

No bottle no labeling, It can monitor and correct automatically if there will be no label

This Machine can be used not only single but also joining in automatic packing line.

Main technical specification:

Productivity 0- 150 bottles/min

Bottle Diameter ф20-ф100mm

Labeling Precision less than ±1mm

Label Length 15-200mm

Label Width 10-100mm

Power Supply 0.5kw

Power 220V/50Hz

Weight 250kg Dimension 2000*950*1300mm

Main Electrical Configuration

|

No. |

Name |

Brand |

|

1 |

Press-button |

Schneider |

|

2 |

Magnetic Contactor |

Schneider |

|

3 |

Relay |

Omron |

|

4 |

Motor |

JSCC made in Germany |

|

5 |

Bearing |

NSK |

|

6 |

Touchscreen |

WEINVIEW |

|

7 |

Fibre-optical |

Autonics |

|

8 |

Switching Mode Power Supply |

NWELL |

|

9 |

Servo motor |

SNAYO made in japan |

Packaging pictures about our machine exported

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse , misapplication, storage damage, negligence, or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE).

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine (The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

Copyright © PENGLAI CORPORATION ALL RIGHTS RESERVED